- #Unigraphics nx vs catia software#

- #Unigraphics nx vs catia code#

The code became a foundation for a product called UNI-GRAPHICS, later sold commercially as Unigraphics in 1975.ġ976 McDonnell Douglas Corporation buys United Computing.

#Unigraphics nx vs catia software#

The company purchases the Automated Drafting and Machining (ADAM) software code from MCS in 1973. releases UNIAPT, one of the world's first end-user CAM products.

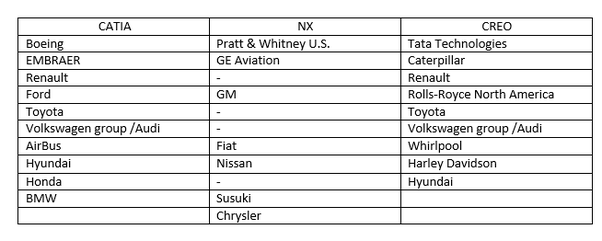

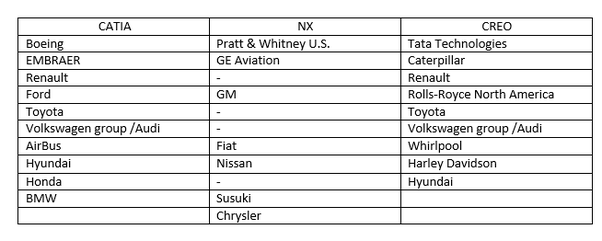

4 Supported operating systems and platforms. And this I think is only because the designers do not want to spent time with this "unimportant" feature for them. Again I do not work with Pro-e and probably I am missing somethig, but one thing I know for sure that all designs coming from Pro-E have missing drafts, all 100%. Probably I am thinking having in maind how it works in I-deas but we have two other costumers that uses Peo-E aswell and they confirmed the same thing that "The only way to have draft for injection molded parts (there is not only one draft value) is to go after the extrusion/protrusion and add it". Since you do not have draft on the first square extrusion you need to add it after, my question is what happend with the round protrusion when draft of 3 degrre is added on the base extrusion, I think that the position of the round protrusion is changed since that is constrained to the top edge of the base extrusion. 400" from the other edge and than you extrude it by.500". 25" diameter which you constaint with a dimension. 500" height, than you scetch on the top face and draw a circle. Lef assume that you extrude a square 1"x1" in. Where you have shoot-offs you nedd more draft than in a surface that do not have shoot-offs.īut I think even during design process you have to be carefull because your part is design in a assambly envoirement, so you need to keep the relations(clereances) from the other parts.Īnother problem is within the part itself. In injected molded parts draft is not the same in all the surfaces. RE: PROE vs Unigraphics vs Solidwoeks vs Catia demco (Automotive) 28 Sep 04 12:32 I think the best in the market today are Catia V5 and UG NX. Only for that reason we discarded the otipn to go to Pro-E since I-deas is going to desappear. Than I understand why he do not add draft, adding draft in injection molded parts in Pro-E is a big pain when you dealt with parts that have 40-50 extrusions and each extrusion has at least 4 surfaces, can you imagine what a lost of time is for a designer of plastic molded parts to design in pro-e, even if there are slight advantages in other areas. He explained that in Pro-E for adding draft in a surface you have to go after extrusion and add it on each surface. So, I went to his office and explained him where the problems are since we have to do around 20 molds for him. This is a very painful process because we have to do the work that he did not do and he do not consider that a work (he belive that the part is already finished in design by him). I noticed that all his designs (all plastic injection molded parts) do not have draft at 100% but 30-40%.Because we have to add draft on the surfaces in order to make it moldable we need to know where that paricular part goes in assembly. I am designin with SDRC I-deas and we are working with a costumer wich uses Pro-E. In my honest opinion, Unigraphics is head over heals the best CAD solution available.īest Regards, RE: PROE vs Unigraphics vs Solidwoeks vs Catia Tetragrammaton (Aerospace) 4 Dec 02 07:53 I know many people who like it but I would tend to stay away from it because is does not scale at all to the growth of your company. I know many companies reverting back to CATIA V4 (which is like working back in the stone ages) because CATIA V5 can not do their job. You can ask many of the large companies using it that question. It has been developed for over four years and is still not production ready. CATIA V5 is a good tool but it is far to unstable and not even close to the capability of Unigraphics. ProEngineer is known for being too difficult to use.

It is very common to design yourself into a corner using ProEngineer. ProEngineer is far to constricting of a tool. It is also the easiest tool to trouble shoot if there are problems with your design. What is most important is associativity (if a change is made, will all your other work update) Unigraphics is by far the most capable tool in this regard. You can use parametrics if you want but if it does not lend itself well to your work then you don't have to. You can use solids, surfaces, wireframe all mixed together. As a design tool, Unigraphics is the most flexible. There is no other tool that can handle customer data easier than Unigraphics. It is the most robust, most stable and most flexible tool available.

In my opinion, Unigraphics is the best tool. I am currently using Unigraphics, ProEngineer, Catia V4 and V5.

0 kommentar(er)

0 kommentar(er)